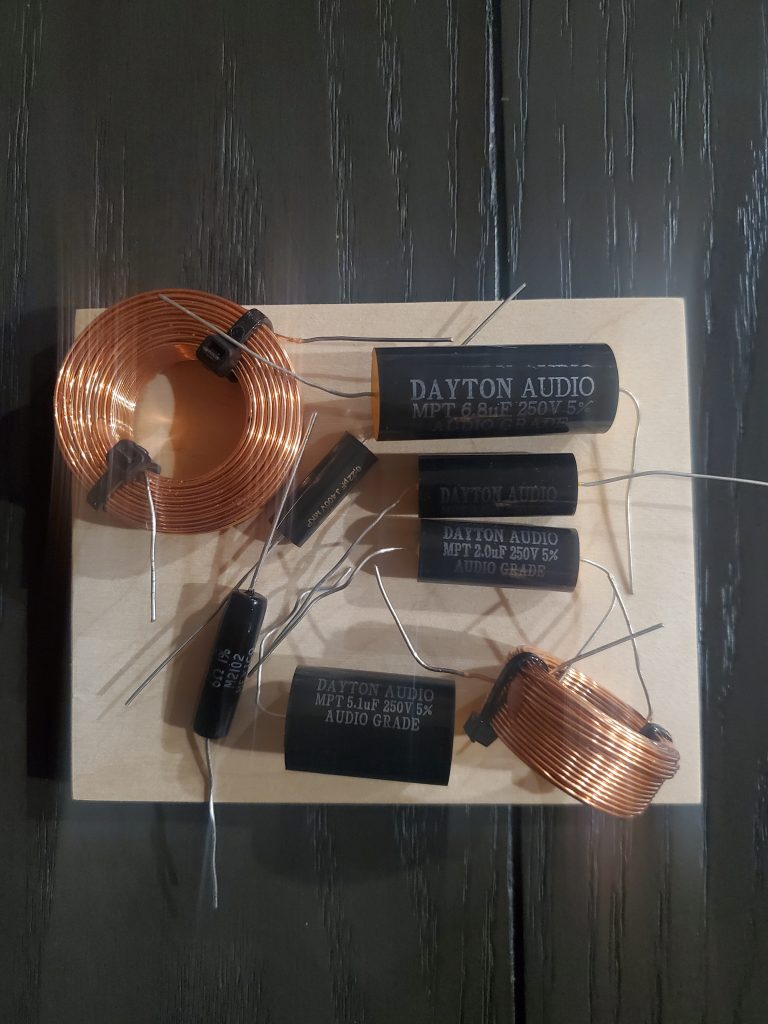

Here’s a few build-photos to show what processes are used and what is included with the service.

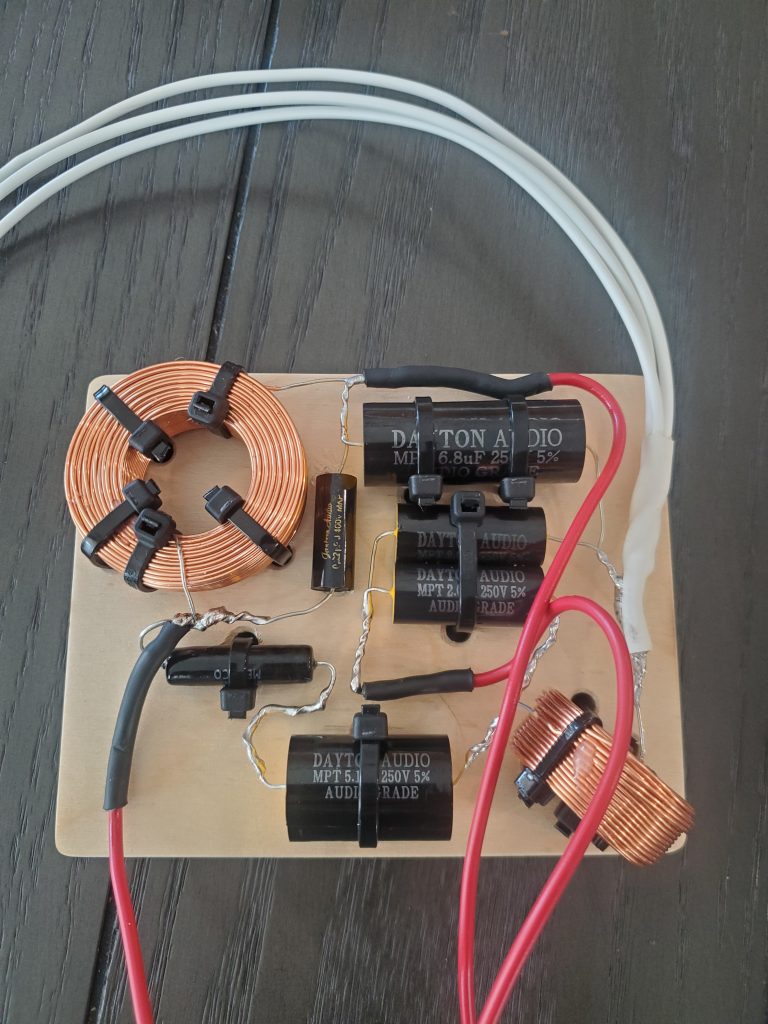

I will cut layout boards that fit your components and your speaker cabinets.

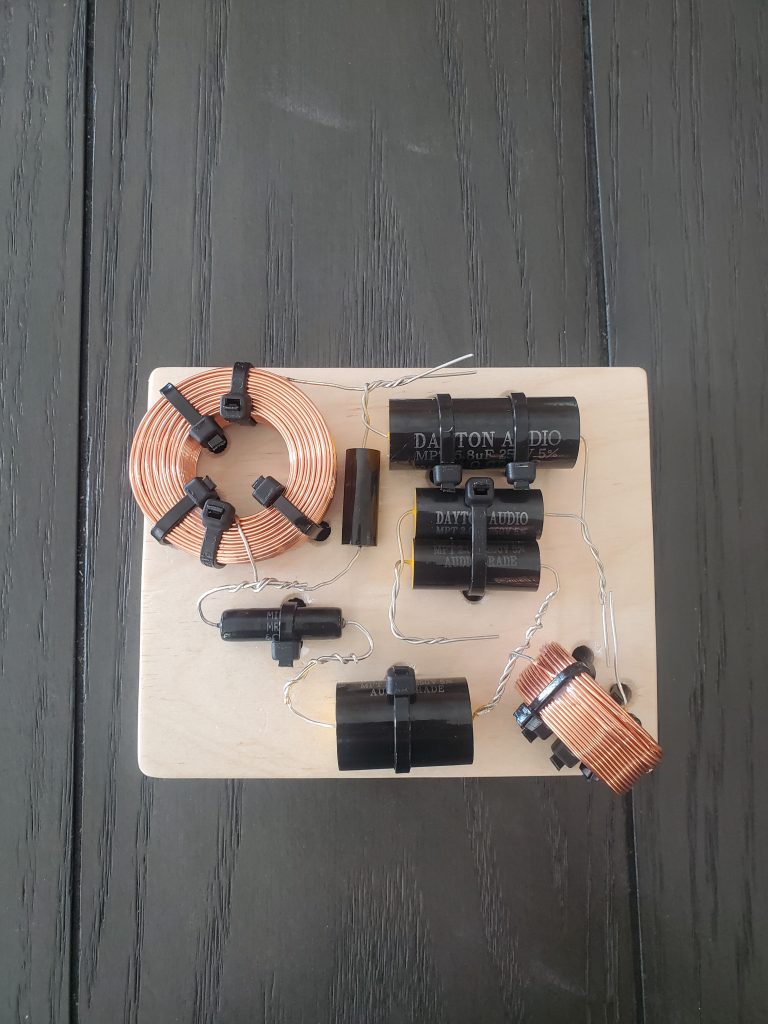

After determining apropriate layout, holes are drilled to secure components with zip-ties. Wood surfaces are smoothed, edges are rounded.

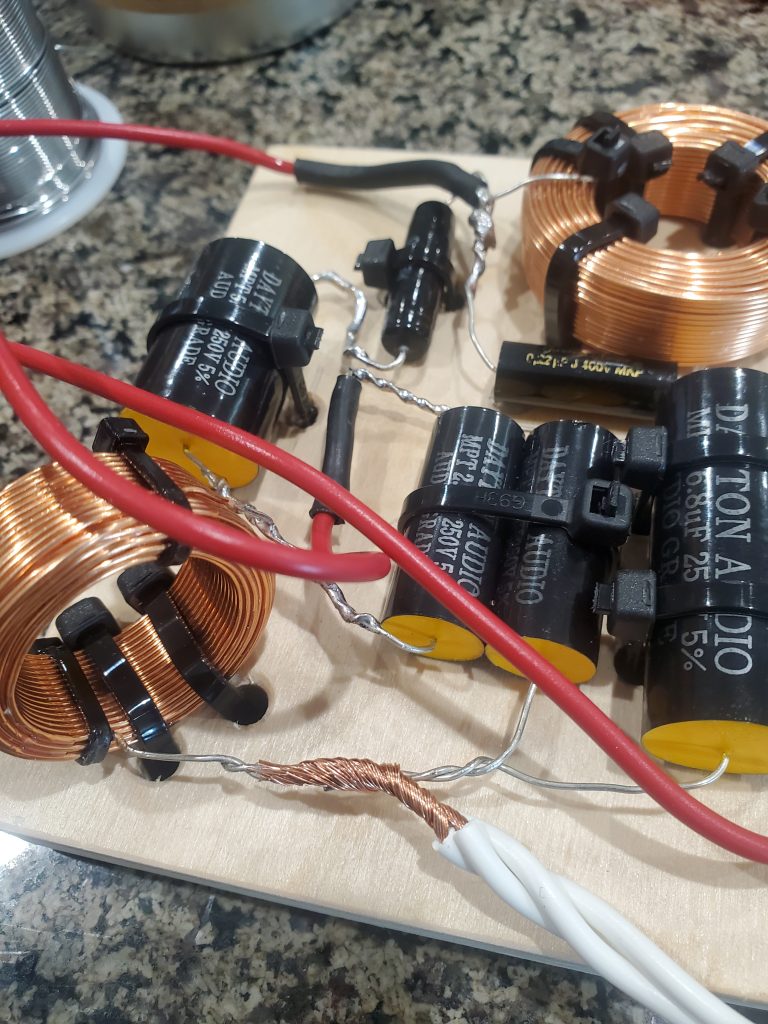

Adding a chamfer to the drilled holes removes the sharp edge and allows the zip-ties to lay as flush as possible on the underside.

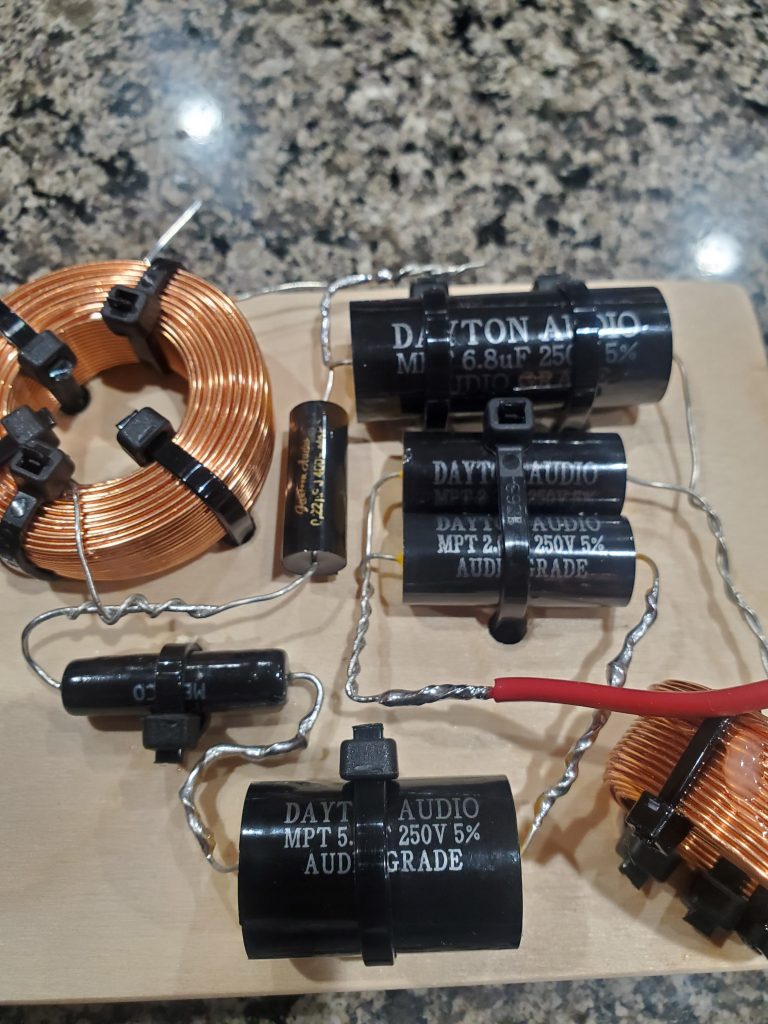

Mechanical connections are made according to the crossover schematics. An end-to-end method is used, twisting together the leads of corresponding components without having to add additional jumper wires which could detract from the signal.

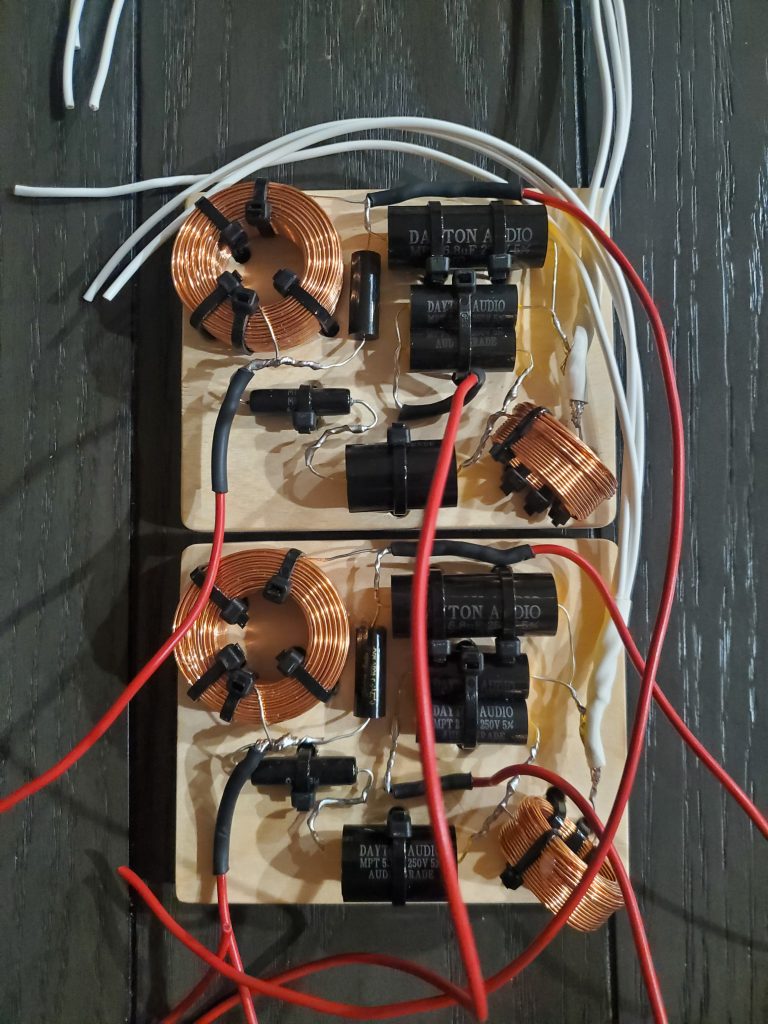

Interior connection wires are soldered directly to the crossover. This method is preferred instead of using terminals which add unnecessary material into the signal path.

Adding terminals to the crossover boards is avoided since placing additional elements into the circuit path may cause a negative impact.

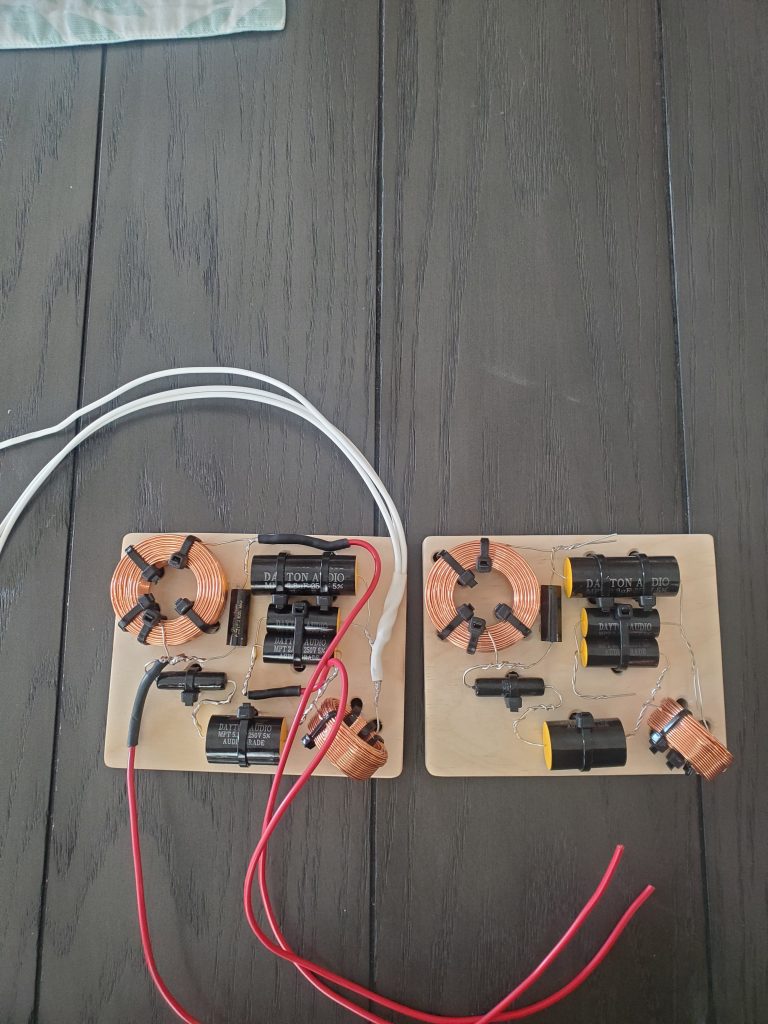

Here is a matched pair of crossovers for visual comparison. One has internal wiring added, the other does not.